Sublimation

The Process

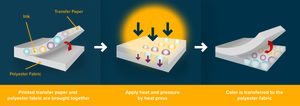

The sublimation process is a printing technique that involves converting solid ink directly into a gas, bypassing the liquid phase, and infusing it into a substrate, typically a polyester-based material or coated hard surface. This process is widely used for creating vibrant, durable, and high-resolution images on products such as clothing, mugs, phone cases, and more. The sublimation process results in a long-lasting, high-quality print that is resistant to fading, peeling, or cracking, as the ink becomes a part of the substrate's structure.

Why Choose Sublimation?

Sublimation offers several benefits as a printing technique, making it an attractive choice for creating custom products and designs. Some of these benefits include:

1. Vibrant Colors:

Sublimation inks produce bright, vivid colors with a wide color gamut, resulting in high-quality images that are true to the original design.

2. Durability:

Sublimated prints are long-lasting and resistant to fading, peeling, or cracking since the ink is infused directly into the substrate's surface, becoming a part of its structure.

3. Soft Feel:

Unlike other printing methods that leave a noticeable texture on the surface, sublimation creates prints that are smooth to the touch, making it especially suitable for clothing and textiles.

4. Full-Color Printing:

Sublimation allows for full-color, photographic-quality prints without the need for additional colors or screens, making it cost-effective for small-scale and one-off projects.

5. No Minimum Quantity:

Sublimation is an on-demand printing technique, making it ideal for creating custom products in small quantities or even single pieces without incurring high setup costs.

6. Versatility:

Sublimation can be used on a wide range of polyester-based materials and polymer-coated surfaces, including clothing, mugs, phone cases, metal panels, and more, offering flexibility in product applications.

7. Design Flexibility:

Sublimation allows for intricate and detailed designs, including gradients and photographic images, without losing resolution or quality during the printing process.

8. Eco-friendly:

Sublimation is a relatively eco-friendly printing method, as it uses water-based inks, generates minimal waste, and doesn't require harsh chemicals for cleaning or processing.

9. Quick Turnaround:

The sublimation process is relatively fast, enabling quick turnaround times for custom products, particularly for small-scale or on-demand projects.

10. No Ink Build-up:

Since the ink is infused into the substrate, there is no ink build-up on the surface, ensuring consistent print quality throughout the product's lifespan.

These benefits make sublimation an ideal choice for creating high-quality, durable, and customizable products in various applications, including apparel, promotional items, and personalized gifts.